Galvanized Iron GI sheets have become staple materials in the construction industry due to their durability, resistance to rust and low price. Out of all the available types, corrugated GI sheets and plain sheets are the most popular ones. Even though both sheets consist of galvanized steel, their shape, characteristics, and areas of application are quite different. The main differences, pros and cons, and best applications of corrugated and plain GI sheets will be discussed in this blog so that you can select the most suitable one for your project.

What Are Corrugated GI Sheets?

Corrugated GI sheets feature a wavy or ridged pattern formed by rolling the sheet into alternating crests and troughs. This design improves structural strength without increasing material thickness.

Key Features

- High load-bearing capacity

- Excellent water drainage

- Increased rigidity

- Lightweight yet strong

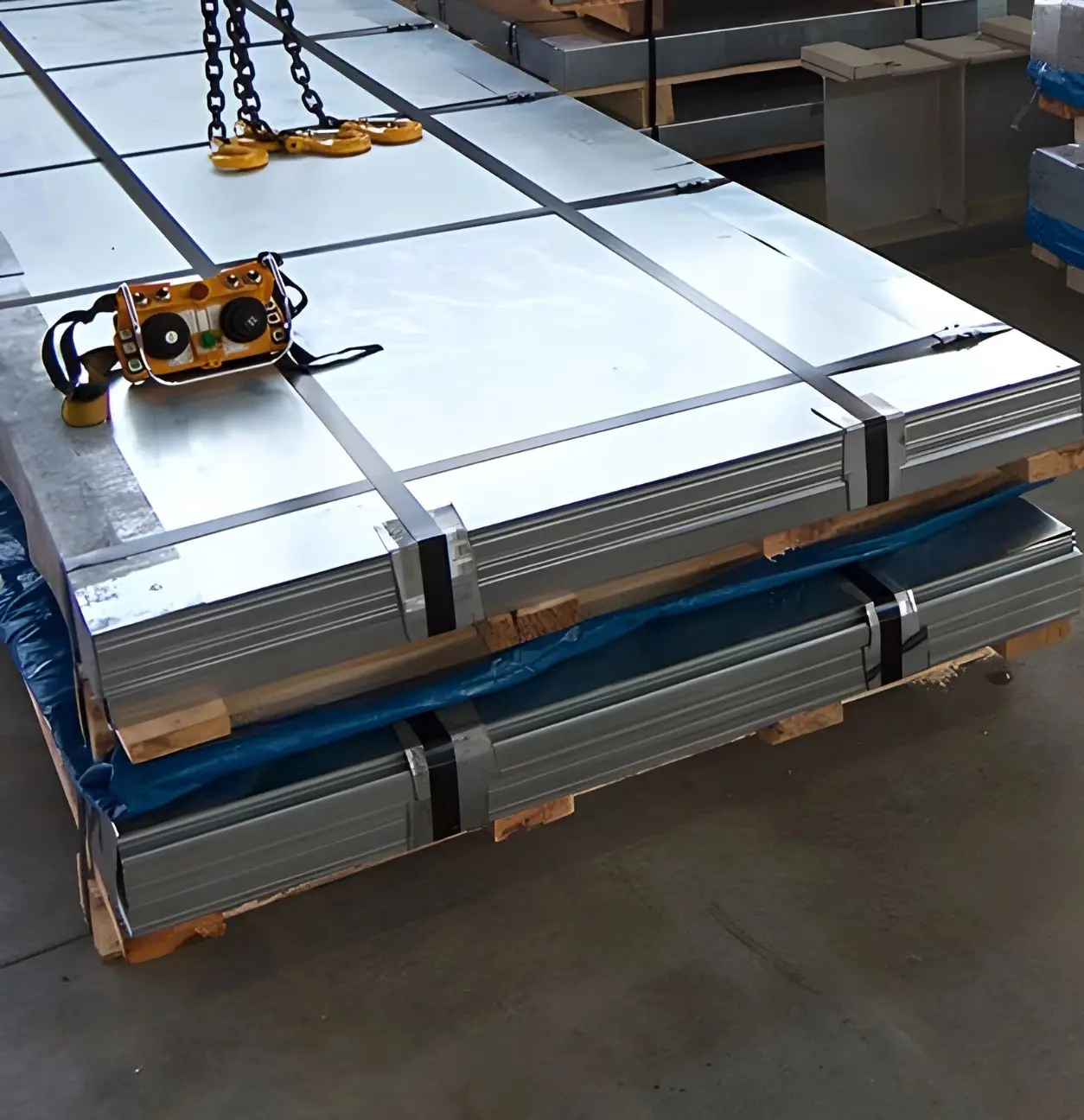

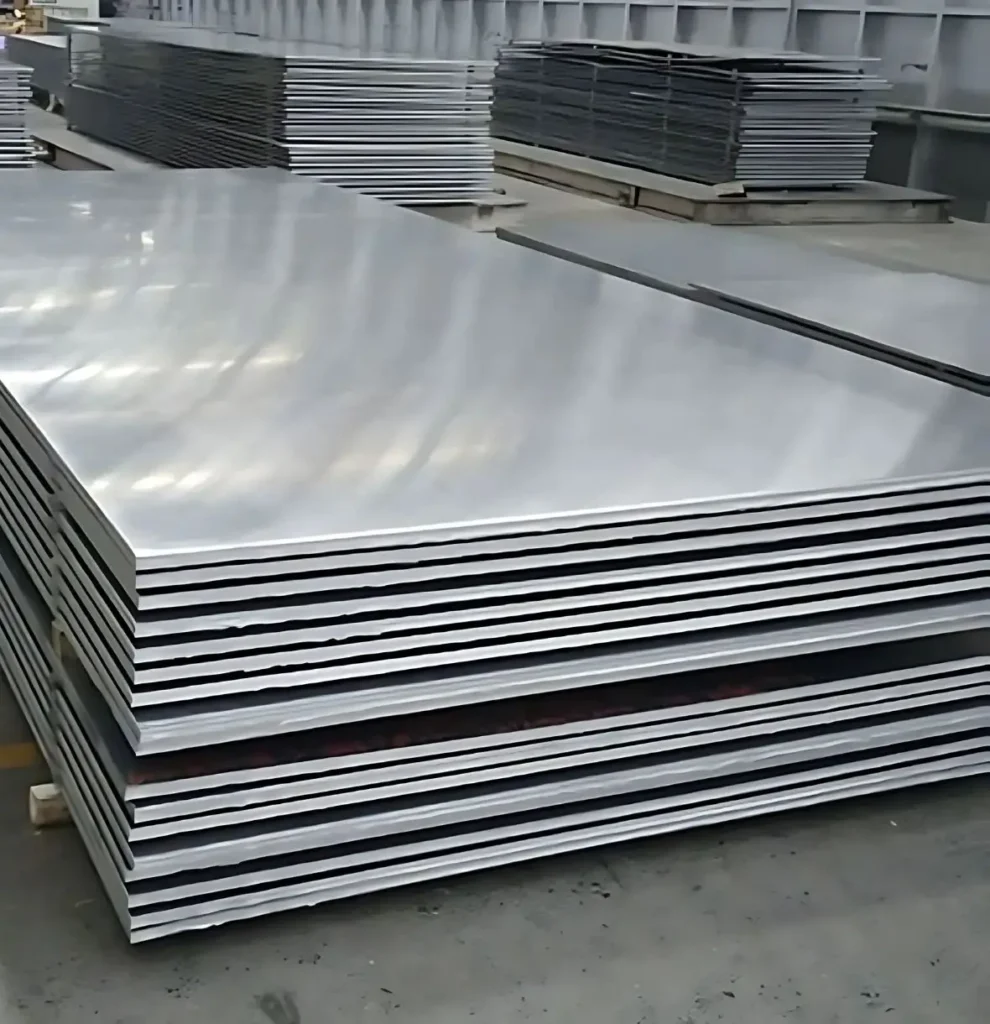

What Are Plain GI Sheets?

Plain GI sheets have a flat, smooth surface with no ridges or patterns. They are versatile and easy to cut, bend, and fabricate.

Key Features

- Smooth and uniform surface

- Easy to fabricate and customize

- Cost-effective for secondary uses

- Ideal for forming and bending

Corrugated vs Plain GI Sheets: Key Differences

| Parameter | Corrugated GI Sheets | Plain GI Sheets |

|---|---|---|

| Structural Strength | High | Moderate |

| Load Capacity | Excellent | Limited |

| Water Drainage | Very good | Poor (needs slope/support) |

| Weight | Lightweight for strength | Lightweight but less rigid |

| Fabrication Ease | Limited | Excellent |

| Aesthetic Appeal | Industrial | Clean & minimal |

| Cost | Slightly higher | Generally lower |

Best Applications for Corrugated GI Sheets

Corrugated GI sheets are preferred where strength and weather resistance are critical.

Ideal Uses

✔ Roofing for industrial sheds & warehouses

✔ Agricultural buildings and farm sheds

✔ Factory roofs and workshops

✔ Temporary shelters with exposure to rain

✔ Parking sheds and bus shelters

Why Choose Corrugated?

The corrugated design provides natural stiffness, allowing sheets to span larger distances without sagging. This makes them ideal for roofs and outdoor structures.

Best Applications for Plain GI Sheets

Plain GI sheets are commonly used in fabrication and indoor applications.

Ideal Uses

✔ Wall cladding and partitions

✔ Fabricated enclosures and panels

✔ HVAC ducts and electrical panels

✔ Furniture and cabinets

✔ False ceilings and interior applications

Why Choose Plain Sheets?

Their flat surface makes them easy to cut, weld, bend, and shape, making them suitable for customized fabrication work.

Durability & Weather Performance Comparison

- Corrugated GI Sheets: Better performance in rain and wind due to shape and drainage ability

- Plain GI Sheets: Require support and proper slope to avoid water accumulation

For outdoor roofing, corrugated sheets outperform plain sheets in terms of longevity and maintenance.

Cost vs Performance Consideration

- Corrugated sheets may cost slightly more but reduce structural support costs

- Plain sheets are cheaper initially but may require additional framing for strength

👉 Always evaluate total project cost, not just material price.

Which GI Sheet Should You Choose?

Choose Corrugated GI Sheets if:

- The application is roofing or outdoor

- Load-bearing and drainage are important

- You need durability with minimal support

Choose Plain GI Sheets if:

- The application involves fabrication or interiors

- Custom shaping or bending is required

- Structural load is minimal

Additional Factors to Consider

Regardless of type, ensure:

- Proper zinc coating thickness (180–275 gsm recommended)

- Appropriate gauge selection (22G–26G based on load)

- Compliance with industry standards

- Reliable supplier and quality certification