Introduction

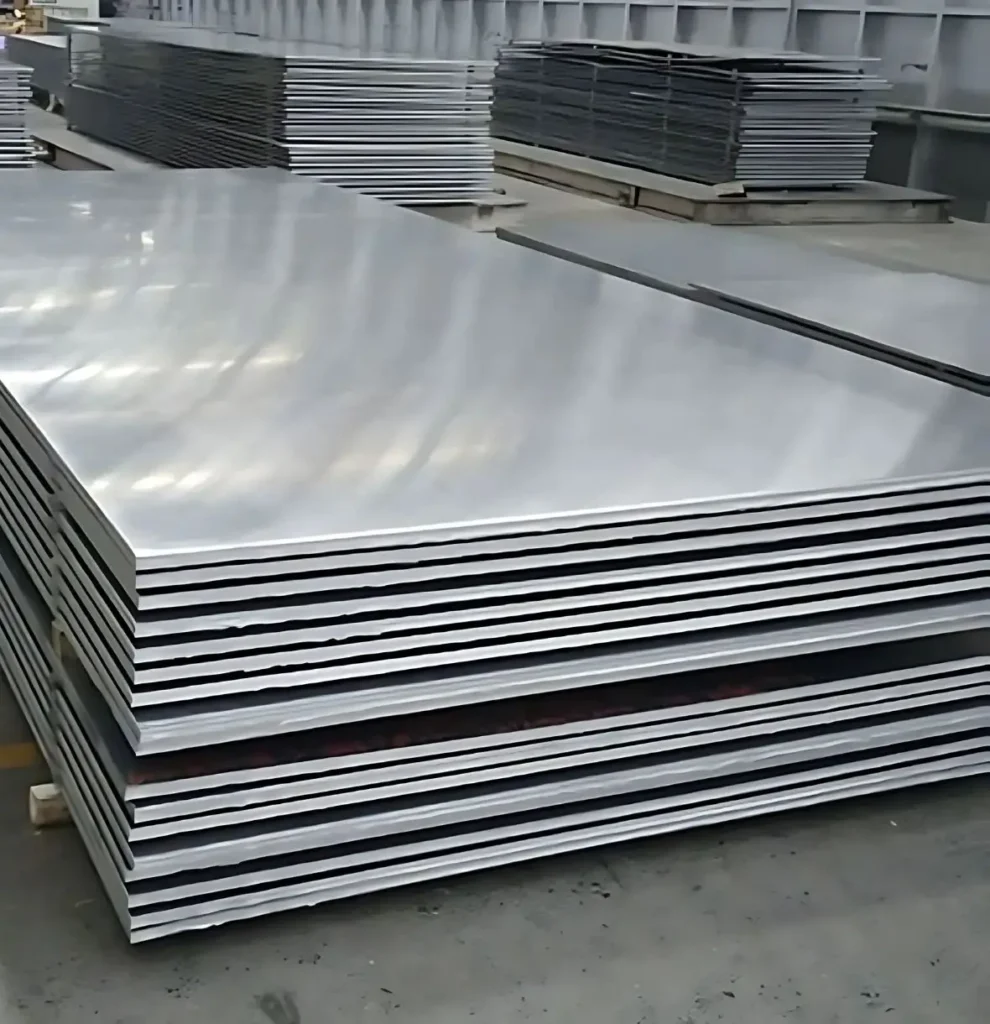

The construction industry has evolved tremendously over the years, with modern materials enhancing both the strength and longevity of buildings. Among these materials, Galvanised Iron (GI) sheets stand out as one of the most versatile and widely used. From roofing and wall cladding to fencing, ducting, and even in the automotive sector, GI sheets have proven their value through durability, corrosion resistance, and cost-effectiveness.

But not all GI sheets are the same, and more importantly, not all suppliers are equal. A high-quality product from a trusted GI sheet supplier can ensure that your project stands the test of time. On the other hand, working with an unreliable supplier can lead to poor quality, hidden costs, and delays that put your entire project at risk.

That’s why asking the right questions before purchasing is crucial. Whether you are a contractor managing a large-scale industrial project, a builder sourcing materials for residential housing, or even a homeowner looking for roofing solutions, these questions will help you evaluate your supplier and make the right decision.

In this article, we’ll explore eight essential questions to ask your GI sheet supplier before making a purchase. These questions will not only help you identify the right supplier but also save you from costly mistakes in the long run.

Question 1: What Grades and Thickness Options Do You Offer?

When evaluating a GI sheet supplier, the first thing you should look into is the range of grades and thicknesses they provide. GI sheets come in a variety of grades, and each grade is designed for a specific application. For example, lightweight sheets may be suitable for residential roofing, while thicker, heavy-duty sheets are essential for industrial projects.

A good supplier should provide options such as:

- Regular spangle and zero spangle sheets – depending on whether aesthetics or durability is the priority.

- Different zinc coating thicknesses – more coating provides better resistance against corrosion.

- Custom thicknesses – from as low as 0.15 mm up to 3 mm or more, depending on the project requirements.

Why this matters:

- Durability – Thicker sheets last longer and provide better protection against harsh weather.

- Application-specific – Industrial warehouses, coastal projects, and rural roofing all require different grades and thicknesses.

- Cost optimization – Choosing the correct thickness ensures you don’t overspend on unnecessary material.

If a supplier offers very limited choices, it could be a red flag. A trustworthy GI sheet supplier will not only provide multiple grades but also help you choose the right one based on your project’s needs.

Question 2: How Do You Ensure the Quality of Your GI Sheets?

Quality is non-negotiable when it comes to GI sheets. One of the biggest mistakes buyers make is assuming all sheets are the same. In reality, there can be a huge difference in terms of zinc coating, tensile strength, and overall finish.

When talking to your supplier, ask about their quality assurance processes:

- Do they follow Indian Standards (IS 277) or equivalent international standards?

- Do they provide test certificates for zinc coating thickness?

- Do they have ISO certifications for their manufacturing process?

- Do they conduct corrosion resistance testing?

Suppliers who value quality will have no problem sharing their certifications and test reports. In contrast, suppliers who avoid these discussions may be selling substandard products.

Why this matters:

- Long-term performance – A high-quality GI sheet resists rust, reducing maintenance costs.

- Project safety – Substandard materials can compromise structural integrity.

- Value for money – Paying slightly more upfront for certified quality saves you costly repairs later.

Always remember: a reliable GI sheet supplier is transparent about quality standards.

Question 3: What Is the Pricing Structure and Are There Hidden Costs?

Price is always a major factor in material procurement, but it’s important to look beyond just the base price of GI sheets.

Suppliers may price sheets based on:

- Per sheet – common for retail buyers.

- Per square foot – useful for roofing projects.

- Per kilogram – common in wholesale transactions.

But the real question is: What’s included in the price?

Some suppliers may add hidden charges for:

- Freight and transportation

- GST and other taxes

- Cutting or customisation fees

- Unloading charges at the site

Why this matters:

- Transparency – You should know the final landed cost before confirming the order.

- Budget planning – Hidden costs can derail project budgets.

- Trust – Honest suppliers are upfront about their pricing structure.

When comparing suppliers, don’t just look at the unit cost of GI sheets. Instead, evaluate the total cost of procurement.

Question 4: Can You Provide Custom Sizes or Finishes?

Every project is different, and sometimes standard sheet sizes don’t fit your requirements. That’s where a supplier’s ability to customize sizes or finishes becomes valuable.

Customization may include:

- Cutting to required lengths – reduces wastage and labor costs on-site.

- Corrugation options – for roofing, wall cladding, or fencing.

- Color coating – if aesthetics and brand alignment matter.

- Special coatings – for environments with high humidity or salinity.

Why this matters:

- Efficiency – Custom sheets fit directly into your project design.

- Reduced waste – No need to cut or discard excess material.

- Professional finish – Aesthetically pleasing and project-specific results.

A professional GI sheet supplier who offers customization shows they are serious about meeting client needs rather than just making a sale.

Question 5: What Is the Minimum Order Quantity (MOQ)?

One critical but often overlooked aspect of procurement is the minimum order quantity (MOQ).

- Wholesalers may require large MOQs, which may not be practical for small projects.

- Local distributors may allow smaller orders, but often at a higher per-unit price.

Why this matters:

- Small contractors can avoid over-purchasing.

- Large projects can ensure they get consistent batches of sheets.

- Cost efficiency – Buying too much stock ties up capital, while buying too little can cause delays.

Ask your GI sheet supplier if they are flexible with MOQs, especially if your project requires a phased approach to procurement.

Question 6: What Are Your Delivery Timelines and Logistics Support?

Even the best GI sheets are useless if they don’t arrive on time. Delivery timelines are crucial in the construction industry, where delays can cause huge financial losses.

Questions to ask:

- Do they have ready stock of commonly used sizes?

- What is their average lead time for delivery?

- Do they provide logistics support, including loading and unloading?

- How do they handle urgent orders?

Why this matters:

- Project timelines – Late deliveries can hold up entire projects.

- Cost implications – Idle labor and delayed schedules cost money.

- Peace of mind – A reliable supplier ensures material availability when needed.

An experienced GI sheet supplier often has strong logistics partnerships, ensuring smooth and timely deliveries.

Question 7: Do You Offer After-Sales Support or Warranties?

A GI sheet supplier’s role should not end once the delivery is made. Reliable suppliers back up their products with after-sales support and warranties.

This may include:

- Warranties against rusting or coating failures.

- Guidance on installation best practices.

- Replacement policies for defective materials.

Why this matters:

- Risk management – A warranty protects your investment.

- Customer support – Knowing you can reach out for help builds confidence.

- Long-term trust – Suppliers who offer warranties are confident in their product quality.

Choosing a supplier with no after-sales service can leave you stranded in case of issues.

Question 8: Can You Share References or Case Studies?

Reputation speaks louder than promises. A dependable GI sheet supplier should be able to share references, testimonials, or case studies from past clients.

What to look for:

- Client references – Contactable past customers.

- Project case studies – Documented examples of successful deliveries.

- Online reviews and ratings – See what others say about their service.

Why this matters:

- Credibility – Past performance is the best predictor of future reliability.

- Peace of mind – Knowing others trust the supplier builds confidence.

- Risk reduction – Verified references reduce the risk of fraud or poor service.

If a supplier hesitates to provide references, it could be a red flag.

Conclusion

Choosing the right GI sheet supplier is not just about finding the lowest price—it’s about ensuring quality, reliability, and long-term value for your project. By asking the right questions, you protect yourself from hidden costs, poor-quality materials, and delayed timelines.

Let’s quickly recap the eight essential questions you must ask:

- What grades and thickness options do you offer?

- How do you ensure the quality of your GI sheets?

- What is the pricing structure and are there hidden costs?

- Can you provide custom sizes or finishes?

- What is the minimum order quantity (MOQ)?

- What are your delivery timelines and logistics support?

- Do you offer after-sales support or warranties?

- Can you share references or case studies?

By thoroughly discussing these aspects with your supplier, you’ll be able to make an informed decision that ensures your project’s success.

If you are looking for a trusted GI Sheet Supplier who offers certified quality, transparent pricing, customization, and reliable delivery, reach out to us today. With years of experience and a reputation for excellence, we’re here to ensure your construction project is built on a foundation of trust and quality.